Electronics Contract Manufacturing for Aerospace & Defense

ThermOmegaTech’s Electronics Division specializes in Printed Circuit Board Assembly (PCBA) for the Aerospace and Defense industries. With deep expertise in complex assemblies and a commitment to rigorous quality standards, we deliver circuit card assemblies (CCA) built for life-critical missions on rugged military systems and aircraft.

Why ThermOmegaTech for Aerospace & Defense PCBA?

Our in-house team oversees every aspect of production—design for manufacturability (DFM), sourcing, assembly, and inspection—to ensure your assemblies are delivered on time, on spec, and ready for deployment. We manufacture PCB assemblies for advanced avionics systems including the C-130 Hercules, CH-47 Chinook, KC-46 Pegasus, Bell 407 Helicopter, Boeing 757, Boeing 767, Bombardier Global Express, Kratos SSAT, and the Korean T-50 Golden Eagle. Our team is highly technical, responsive, and focused on long-term relationships. We help you navigate challenges and optimize solutions every step of the way. Our unwavering commitment to technical problem-solving and exceptional customer service is what sets us apart.

PCB Assembly Services and Capabilities

We specialize in turnkey and consignment PCB assembly services for aerospace and defense applications. Our capabilities include:

-

PCB Types: Rigid, Flex, Rigid/Flex

-

Assembly Techniques: (SMT) Surface Mount, Thru-Hole, and Mixed-Technology Processing

-

Processing: Lead & Lead-Free

-

Fine Pitch: Down to 0.3mm (BGA, QFN, QFP)

-

Configurations: Single or Double-Sided

-

Materials: FR4, Rogers, Copper, Ceramic, Duroid, Aluminum, High-Temperature Laminates

-

Substrates: Metal Core Insulated, Copper Substrates

-

Connectors: High-Speed Backplane, Rack-and-Panel, I/O, Fiber Optics, Micro/Miniature Connectors

-

Relays & Circuit Breakers: Signal-Level, Solid-State

-

PCB Layers: Single or Multi-Layer

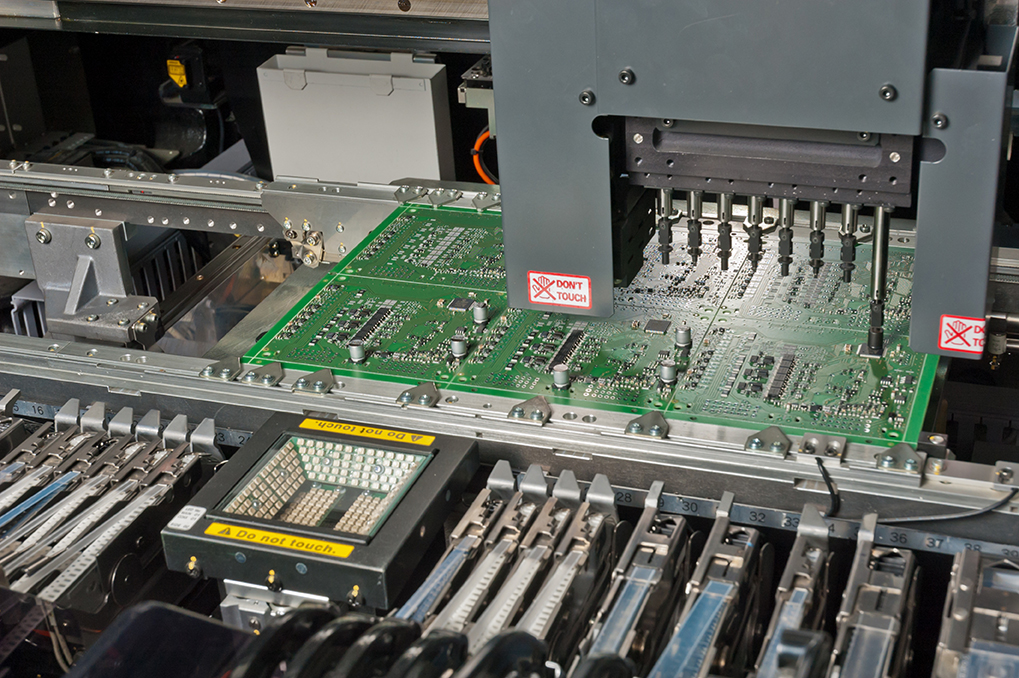

We know that reliability is non-negotiable in aerospace and defense. That’s why we maintain the highest quality standards throughout our facility and circuit card assembly process, as demonstrated by our AS9100D-certified quality management system. We utilize high-speed Pick & Place systems capable of handling 01005 components and fine-pitch packages down to 0.3mm. Our facility features 5-zone and 8-zone ovens, along with a new 13-zone reflow oven with nitrogen atmosphere capability to ensure consistent, high-integrity solder joints. Our automated stencil printer delivers a rapid 15-second cycle time for enhanced throughput, while our 3D Automated Optical Inspection (AOI) systems provide comprehensive inspection and quality assurance. To safeguard sensitive components, we maintain strict environmental controls, including ESD flooring and a centralized humidification system.Advanced Manufacturing Facility

Your Strategic Electronics Manufacturing Partner

At ThermOmegaTech®, we don’t just assemble PCBs—we help you bring your vision to life. Our collaborative approach and flexible electronics manufacturing capabilities make us an ideal partner for aerospace and defense OEMs and suppliers looking to streamline their supply chain without compromising on quality.

Ready to take your electronics to the next level?

Request a quote or contact us on our Electronics Division’s website to discuss your next PCBA project.