Thermal Bypass Valves & Mixing Valves

Effective thermal management is crucial for modern aircraft and ground equipment to ensure rapid warm-up and protect sensitive electronics. ThermOmegaTech® designs thermostatic mixing and diverting (M&D) valves, also known as thermal bypass valves, for precise temperature control in Aerospace and Defense applications.

We offer commercial-off-the-shelf (COTS) valves and cartridges, along with customizable solutions tailored to your exact specifications, including materials, temperature settings, and more.

Discuss Your Project Requirements

How Mixing and Thermal Bypass Valves Operate

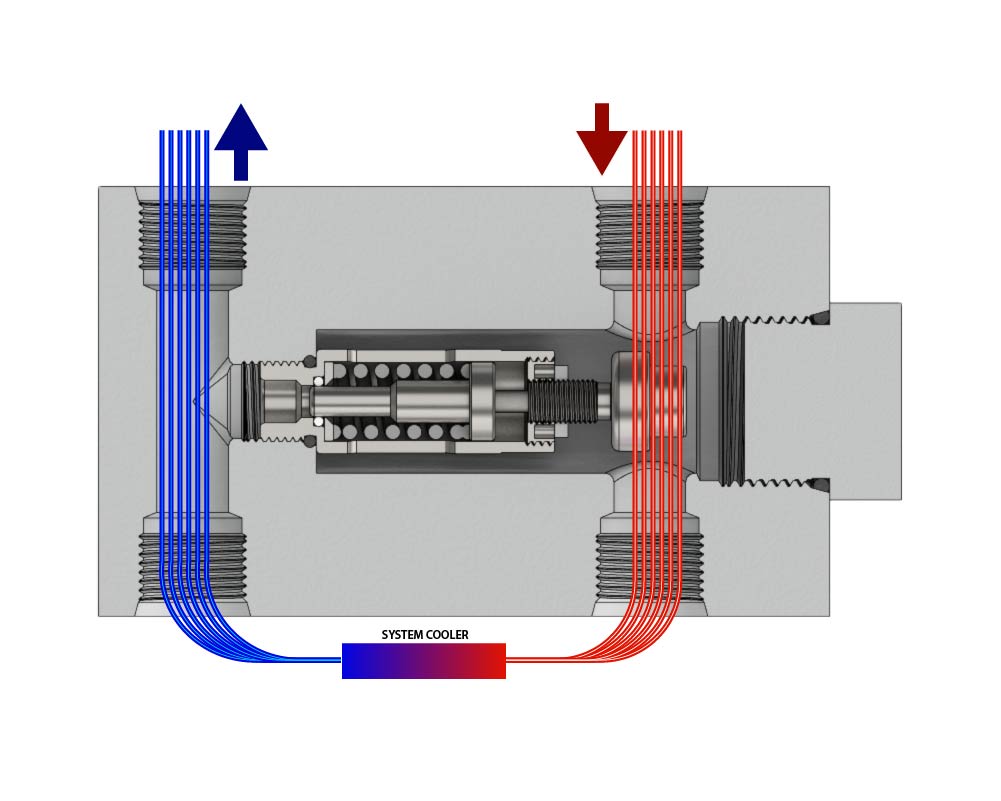

Designed with our exclusive Thermoloid® thermostatic actuator technology, our valves automatically regulate fluid temperature within a narrow and predefined temperature range, ensuring optimal system performance, reduced wear, faster warm-up times, and extended component life. They operate using a thermostatic element, which expands or contracts in response to temperature fluctuations, adjusting internal flow paths accordingly to control system-critical fluids, including coolant, glycol, oil, hydraulic fluid, water, and air.

(Mouse over images to animate)

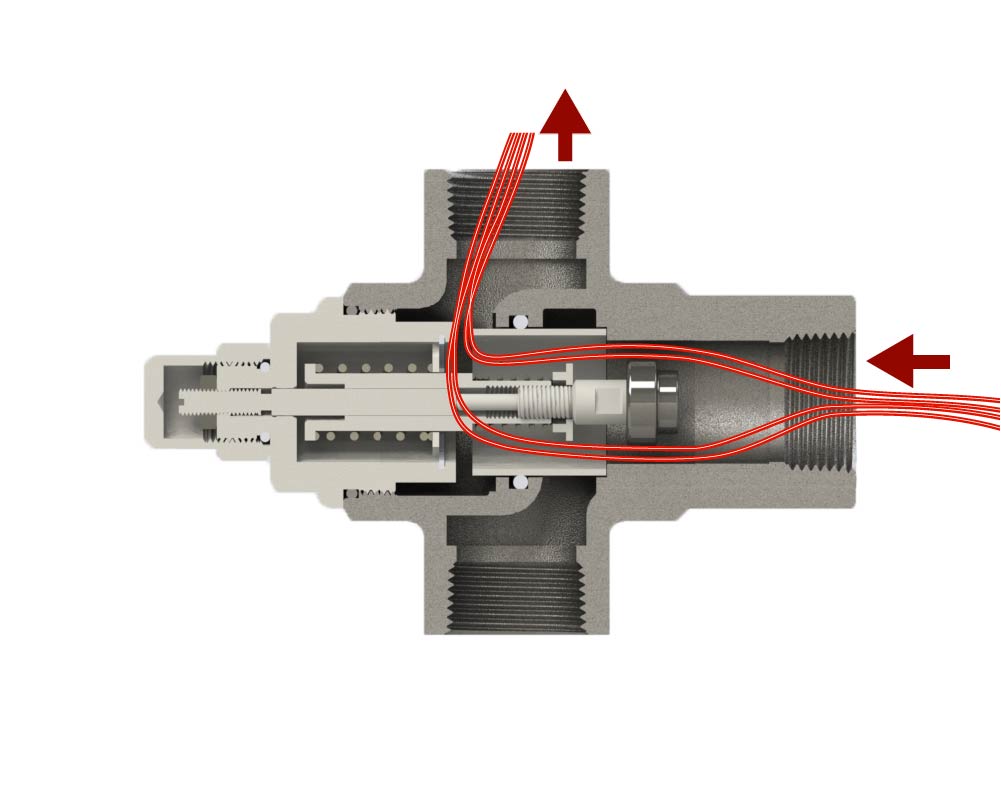

Thermal Diverting Mode

In a 3-way diverting application, the valve directs fluid to one of two outlets based on temperature—bypassing the heat exchanger when cool for faster warm-up and routing through it when fluid reaches the valve’s set-point to prevent overheating.

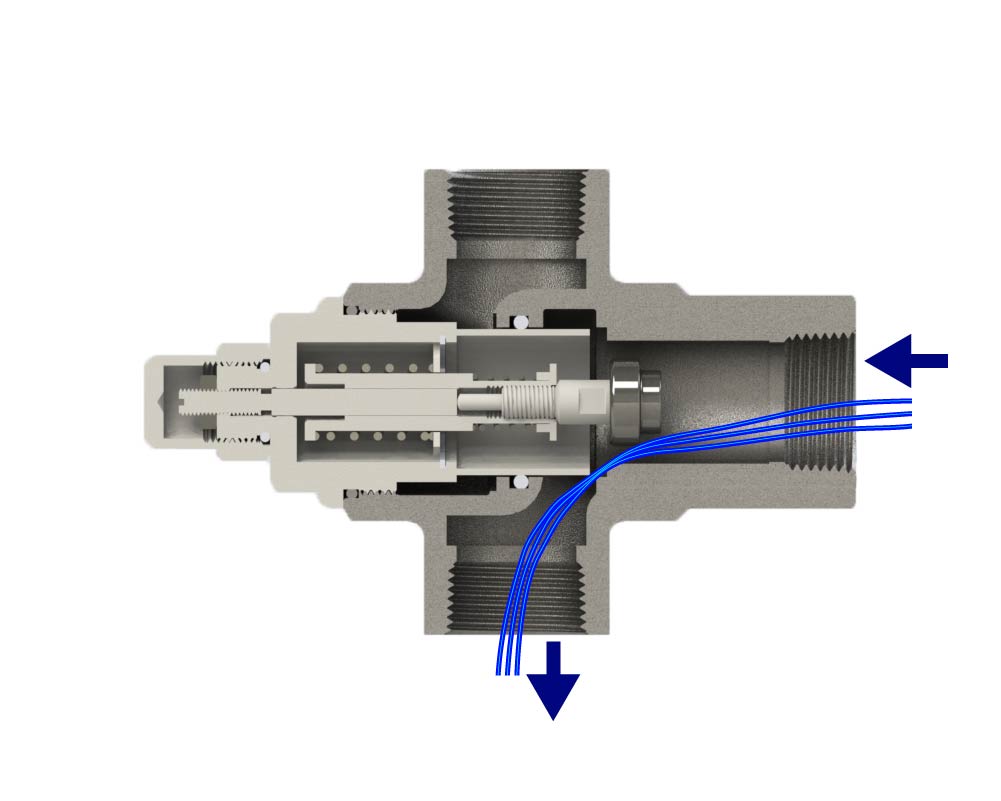

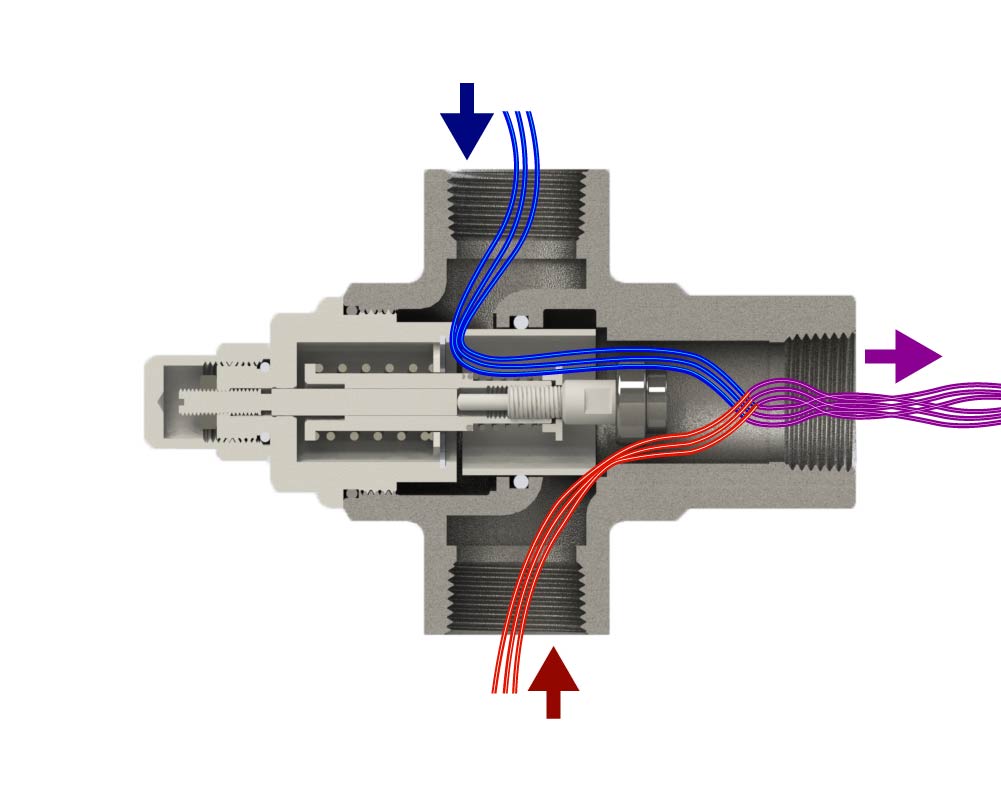

Thermal Bypassing Mode

In a 4-way manifold, the thermal bypass cartridge monitors inlet flow and directs it based on temperature. Above the valve’s set-point, it diverts fluid to the heat exchanger or cooler; below the set-point, it bypasses to the reservoir for recirculation.

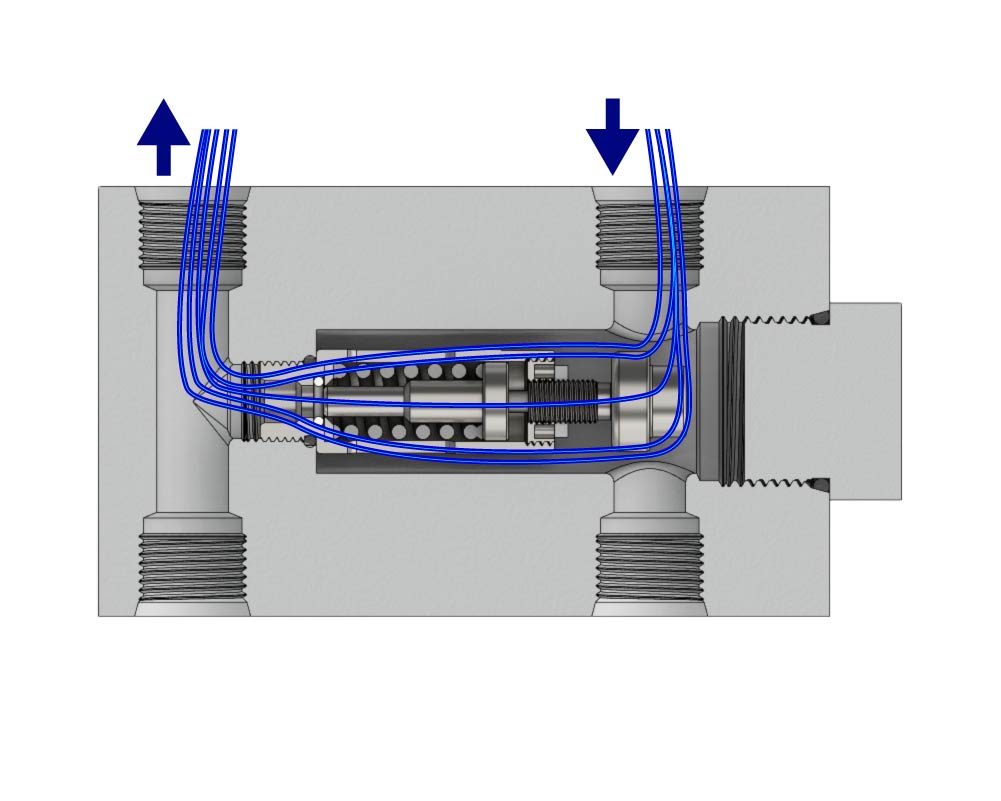

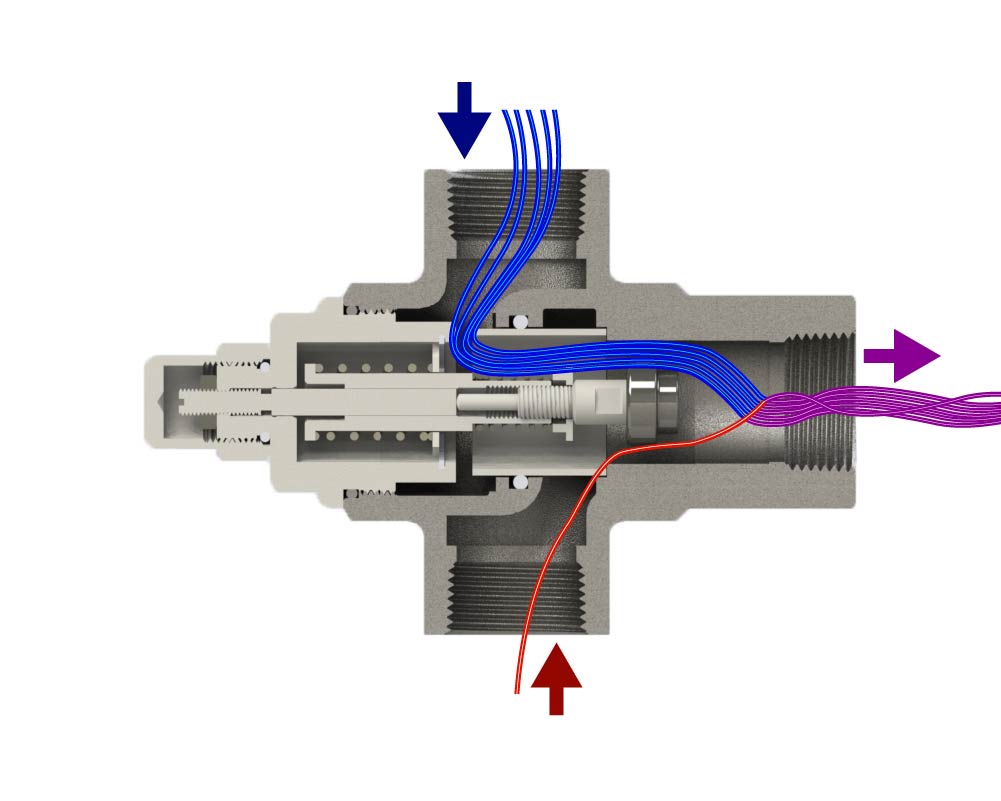

Thermal Mixing Mode

In a 3-way mixing application, the valve modulates between “hot” and “cold” inlet feeds to proportionately mix the fluid to maintain a consistent output temperature.

Benefits

- Self-Operating: No external power source required

- Dynamic: Supports both mixing and diverting applications

- Compact and Low Mass: Fits seamlessly into new or existing system designs

- Thermostatic Element: Responds to temperature changes

- Pressure Independent: Operates effectively under varying system pressures

- Reliable & Low-Maintenance: Durable design with minimal moving parts

Standard Specifications & Literature

- Sizes: ½”, 1”, or 2”

- Materials: 303 Stainless Steel, 316 Stainless Steel, and Brass

- Set-Point Temperature Range: 35°F to 210°F (1.7°C to 98.9°C)

- Seal Materials: Buna-N, EPDM, Viton, or Fluorsilicone

- Maximum Operating Pressure: 350 PSIG (24 BAR)

- Maximum Operating Temperature: 250°F (121°C)

- Mixing and Diverting Brochure

- Aerospace and Defense Brochure

Aerospace & Defense Applications

ThermOmegaTech’s thermostatic mixing and thermal bypass valves have been implemented into dozens of systems throughout the Aerospace and Defense industries to maintain optimal system temperatures in extreme environments—on land, in the air, undersea, and in space.

Common applications include:

- Avionics Cooling – Regulating liquid cooling in military aircraft

- Hydraulic Cold-Start Bypass – Optimizing military vehicle performance

- Fuel Cell Thermal Control – Managing coolant temperature in space & underwater systems

- Environmental Control – Regulating temperature in spacecraft

- Radar & Missile Systems – Liquid cooling for critical electronics & sensors

- Aircraft Ground Support – Managing nitrogen-generation cart temperatures

Cartridge Integration & Customization

Our mixing and thermal bypass cartridges provide a compact, space-saving solution for seamless integration into pre-existing systems requiring thermal bypass or mixing functions. They incorporate the same thermostatic actuator technology as our standard valves but without the housing, allowing for easier manifold integration.

For more information, check out our Valves vs. Cartridges Comparison Sheet.

If our COTS valves or cartridges do not fully meet your project’s requirements, our engineers and project managers will work with you to design a custom solution that solves your thermal control challenge. Changes can be made to a valve’s size, port configuration, body material, O-ring material, temperature settings, stroke, length, thread type, and more.

For lower temperature applications than our standard offering, please complete our custom valve form and submit it to our team.

Let’s Discuss Your Project

We offer Lunch & Learn consultations with our Aerospace & Defense product specialists to explore tailored solutions for your system. As an AS9100D-certified manufacturer, ThermOmegaTech® delivers the quality, precision, and performance your mission-critical applications demand. Contact us today to get started.

Contact Our Design Team