Thermal Actuator Design & Manufacturing Capabilities

Experts in phase-change technology and thermal actuator design, ThermOmegaTech manufactures all the thermal actuators used to power our valves at our facility in Warminster, Pennsylvania. We strive to achieve near-total vertical integration to maintain consistency and control throughout the production process by designing, prototyping, manufacturing, and inspecting all products under one roof. This allows our team to be dedicated to you, your team, and your project as a partner in your success.

ThermOmegaTech is the leading brand for self-powered thermostatic flow control products. Here are a few of the applications our valves and actuators are designed to control.

Check out our brochure to learn how ThermOmegaTech is the partner you can depend on for your thermal control needs.

Key Differentiators

- We have the resources to dedicate time and capital to customized designs to pursue technological advances while ensuring rapid responses and an individualized customer service experience.

- Engineering, manufacturing, assembly, testing, inspection, sales, and customer service departments are all located in one facility for maximum efficiency and effective communication.

- Our 3-year average of 99.5% on-time delivery rate.

- Management dedication to Lean initiatives and Continuous Improvement since 2010, fostering a progressive culture of innovation and improvement.

Custom Engineered Solutions

Our in-house team of experienced, multi-disciplinary engineers has designed dozens of innovative temperature control solutions for Aerospace & Defense applications. In addition to our comprehensive catalog of standard products for thermal bypass, electronics cooling, airflow control, freeze protection, scald protection, and more, we offer custom-design engineering services to satisfy unique product requirements.

Our quality management system is certified to AS9100D standards, demonstrating our focus on quality and meeting the stringent requirements for Aviation, Space, and Defense organizations.

Prior custom valve designs have been implemented in the following Aerospace & Defense applications:

- Hydraulic fluid control

- Avionics cooling control

- UAV airflow control

- Remote underwater release mechanisms

Schedule a Lunch & Learn consultation with our Aerospace and Defense product specialists and design engineers to discuss your temperature control needs.

Federal Supply Class Codes

1440 – Launchers, Guided Missiles

1680 – Miscellaneous Aircraft Accessories & Components

1730 – Aircraft Ground Servicing Equipment

1820 – Space Vehicle Components

2090 – Miscellaneous Ship & Marine Equipment

2541 – Weapons Systems Specific Vehicular Accessories

2930 – Engine Cooling System Components, Non-Aircraft

4510 – Plumbing Fixtures & Accessories

4820 – Valves, Non-powered

Primary NAICS Codes

332911 – Industrial Valve Manufacturing

332721 – Precision Turned Product Manufacturing

332912 – Fluid Power Valves & Hose Fitting Manufacturing

332913 – Plumbing Fixture Fitting & Trim Manufacturing

332919 – Other Metal Valve & Pipe Fitting Manufacturing

336413 – Other Aircraft Parts & Auxiliary Equipment

336419 – Other Guided Missile & Space Vehicle Parts

DUNS: 118072487

CAGE Code: 1FEY0

CERTIFICATIONS: AS9100D

New Product Development

Thermal actuator design and manufacturing on-site allow us the unique ability to customize open and closing temperatures into precise ranges for your applications’ needs. Our engineers can customize the material, valve size, flow rates, number of inlets/outlets, and other optional features such as overrides.

Our product development services include SolidWorks 3D CAD design and Solidworks flow simulations.

Reverse Engineering

We offer mechanical and electrical reverse engineering for obsolete or single-source parts. This service can be stand-alone or combined with additional new product development and testing.

Prototyping

Our product development center is housed in the same building as our manufacturing facility, which allows for prototyping and small-batch runs for your custom designs. Prototyping is often multi-staged, with R&D or field testing in between each batch.

R&D Testing

All new product development is supported by our on-site research and development testing equipment. We utilize a model shop and test stands for pressure, temperature, and flow measurements with wireless DAQ capabilities to ensure correct intended functionality.

Project Management

Our exemplary project management and customer service are at the heart of all our engineering projects. We support you through every step – planning, scheduling, resource forecasting, and technical support – to guarantee a product that will exceed expectations.

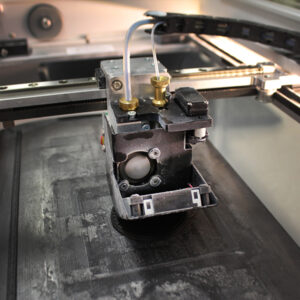

Manufacturing Capabilities

Components used in Aerospace & Defense applications are held to strict standards and often require component traceability and serialization. ThermOmegaTech® is an AS9100D certified production facility with state-of-the-art CNC turning and milling centers controlled by our skilled staff with the help of sophisticated digital systems.

We manufacture valves from precision machined parts in stainless steel, aluminum, titanium, Monel, Inconel, Hastelloy, and other exotic metals to meet the high stress and low weight material requirements of many A&D applications.

Our team maintains a high standard of quality control throughout every step of the production process, offering full part and lot traceability on components for your project.

Machining:

- CNC Turning Centers and Lathes

- DMG MORI NLX 2500/700

- MORI SEIKI SL 150

- STAR 32J & SR20 J

- Mazak Nexus 100, 200 & 250

- Milling Centers

- HAAS VF-2

- Manual Lathes and Milling Machines

- Hardinge SUPER-PRECISION

- Bridgeport

Product Testing:

- Multi-station automated test stand

- Aqueous & hi-temp oil test baths

- Environmental chambers

- LabView Systems

- Industry standards used to validate performance:

- RTCA DO-160

- MIL-STD-810

- Vibration testing via A2LA accredited labs

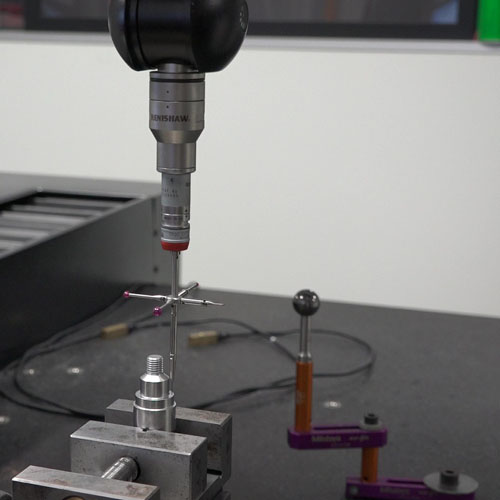

Quality Control:

- Mitutoyo CNC CMM

- Deltronic DH 216 optical comparator

- Olympus handheld XRF – Element analysis and alloy identification

- Dial/Vernier Calipers & Drop Indicators

- Micrometers

- Inside, Depth and Blade Micrometers

- Plug, Ring, and Pin Gauges

- Gauge Block Set

- Measuring tool calibration records traceable to NIST standards