Thermal Actuators

A thermal actuator, also known as a wax motor, is a linear actuator that converts a temperature change into a mechanical force to push/pull, open/close, or move a load using the phase-change properties of paraffin wax. ThermOmegaTech® thermal actuators feature our proprietary Thermoloid® wax-blend material, ensuring precise performance.

The versatility of thermal actuator technology makes it ideal for Aerospace and Defense applications, where reliability is critical in remote, extreme, and unique design challenges. With a simple yet highly effective mechanism, our actuators deliver forceful, self-powered operation for demanding applications.

Discuss Your Project Requirements

How Thermal Actuators Operate

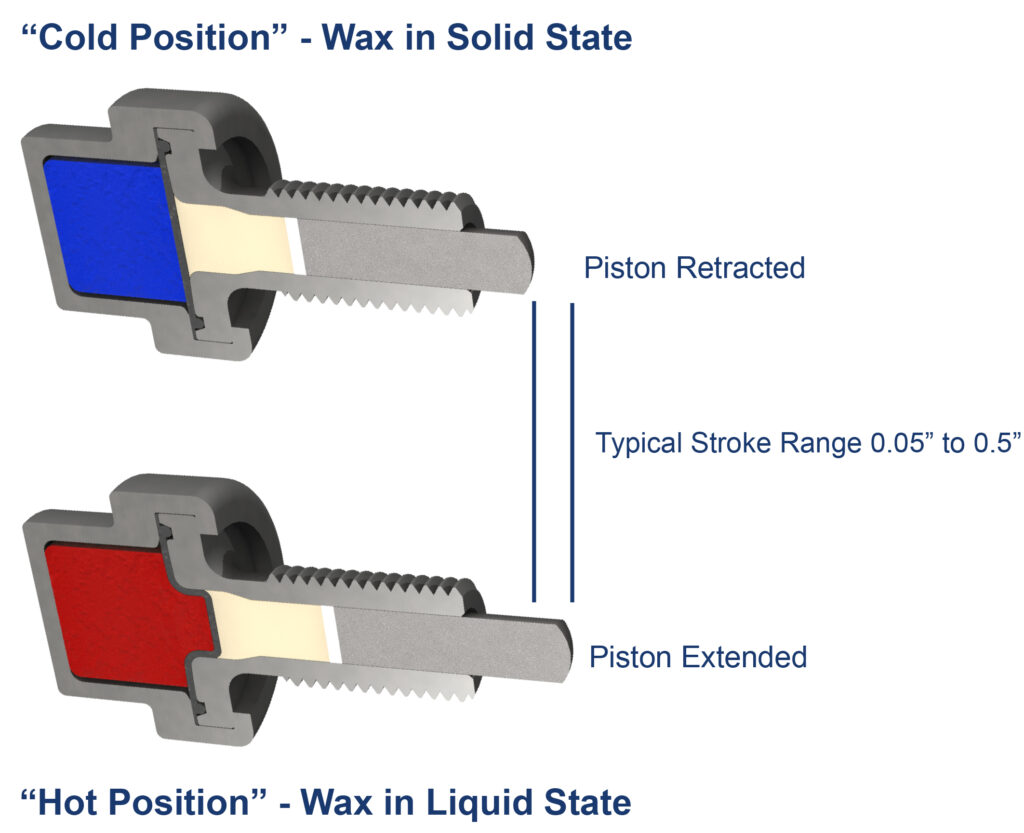

Thermal actuators function by expanding and contracting phase-change wax in response to temperature variations. As the temperature increases, the wax melts and expands, exerting force on a piston to generate linear motion for pushing, pulling, extending, or retracting components.

When the temperature decreases, the wax solidifies and contracts, allowing the piston to return to its original position if a counterforce is applied. This highly reliable, self-powered motion provides precise thermal control, with activation temperatures customizable within a narrow range (typically 10–20°F). Due to the high-density, incompressible nature of the wax, the actuator generates significant force while maintaining a compact, lightweight design.

Benefits

- Self-Actuating: Operates without electrical or external power

- Maintenance-Free: No periodic calibration or service requirements

- Predictable and Precise: Reliable activation temperatures

- Simplistic and Durable Design: Increases service life and minimizes part failures

- Compact and Lightweight:: Optimized for low SWaP (Size, Weight, and Power) requirements

- Resistant to Shock & Vibration: Performs reliably in extreme conditions

Standard Specifications & Literature

- Materials: 303 Stainless Steel, 316 Stainless Steel, and Brass

- Alternative Materials: Duplex 2205 and 2507 Stainless Steel – others available upon request

- Force Output Range: 20lbs. to 150 lbs. (9.07Kg to 68.04Kg)

- Start to Stroke Temp. Range: 15°F to 300°F (-9.4°C to 149°C)

- Max. Stroke Activation Range: 10°F to 20°F (5.5°C to 11.1°C)

- Chemical Treatments: Passivation, Electropolishing, NACE Annealing, Chemfilm, and Anodizing

- Thermal Actuator Product Sheet

- HOPA Product Sheet

- Aerospace and Defense Brochure

Aerospace & Defense Applications

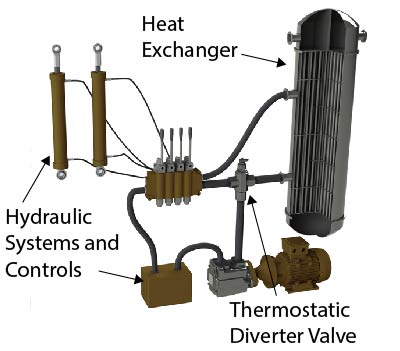

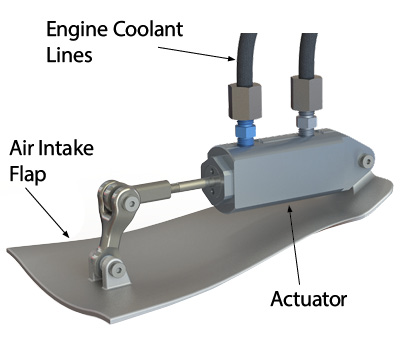

Each ThermOmegaTech® wax actuator is designed to respond within a specific temperature range and can be integrated into a wide variety of bodies, manifolds, and systems for heating, cooling, or activation applications. Their ability to operate autonomously makes them ideal as fail-safe mechanisms in environments where electrical power is unavailable or unreliable. Our actuators are often used to control mixing and diverting valves or cartridges and inline freeze and scald protection valves in mission-critical applications.

Common applications include:

- Military Aircraft – Fuel/oil cooler assemblies

- Military Vehicles – Hydraulic cold-start systems

- Unmanned Aerial Vehicles (UAVs) – Vent door control

High Output Paraffin Actuators (HOPA)

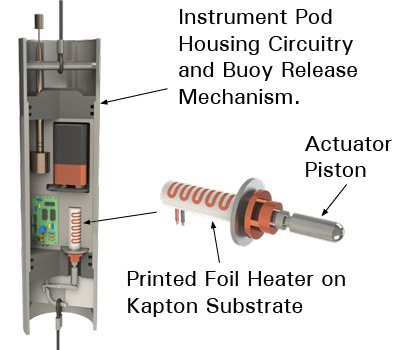

For applications requiring greater force and stroke length, ThermOmegaTech® High Output Paraffin Actuators (HOPA) provide a powerful, self-contained solution. Designed for extreme environments, our HOPAs withstand radiation exposure, extreme temperatures, and high-pressure conditions while operating in both liquid and gas environments. Their simplified design eliminates complex mechanical components, enhancing reliability.

Key Features

- Self-Actuating: Operates without electrical input for reliability in remote locations

- High Output Force: Delivers over 1000 lbf

- Extreme Environment Operation: Performs in vacuum and high-pressure conditions with negligible outgassing

- Safe & Nonexplosive: A secure alternative to traditional explosive release devices

- External Heat Source Activation: Can be triggered by an electric resistor for precise control

Ideal for Aerospace & Defense

HOPA actuators are designed for high-force, precision applications, such as:

- Satellite Deployment Systems: Reliable one-time release mechanisms

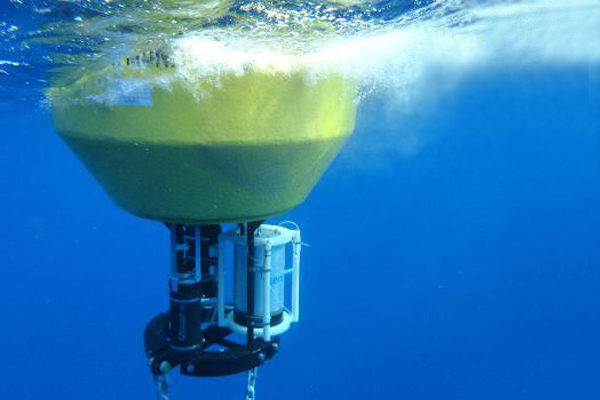

- Space & Deep-Sea Exploration: Actuation in harsh, low-pressure environments

Tailored for Your Application

Thermostatic wax valve actuator technology is incredibly flexible; its parameters can be molded to fit your unique temperature control project and individual vision. If our standard offerings don’t meet your needs, our engineering team can develop custom solutions to specific project requirements, including material selection, elastomer options, and activation temperature ranges. As specialists in valve manufacturing, we can seamlessly integrate your actuator into a complete solution—whether it’s an inline valve, a mixing and diverting valve, or a cartridge configuration.

ThermOmegaTech® thermal actuators and HOPA solutions provide precise, self-powered mechanical motion for the most challenging Aerospace & Defense applications. As an AS9100D-certified and DDTC-registered manufacturer, we uphold rigorous quality standards across every stage of design and production. Please complete our custom valve form and contact us today to discuss your project requirements.

Contact Our Design Team

Past Projects